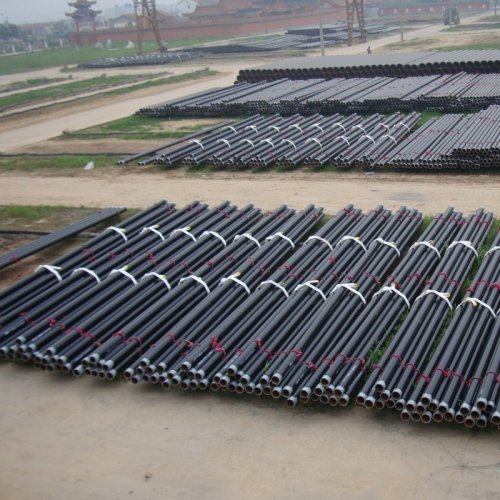

3LPE External Coating Steel Pipe for Oil and Gas Pipeline

Review

Description

Nominal Diameter Range |

Outside Diameters Rang(mm) |

Coating Type |

Coating Layer |

Coating Thickness |

DN100~600 | 114.3~609.6 | 3PE: | Inside Layer: Epoxy (Green) | 2.0~4.5mm |

Mid Layer: Adhesive (White) | ||||

Outside Layer: Polyethylene (Black) | ||||

2PE: | Inside Layer: Adhesive | 2.0~4.5mm | ||

Outside Layer: Polythene | ||||

DN80~600 |

88.9~609.6 |

FBE: Epoxy |

Epoxy |

200~400um |

|

2FBE: |

Inside Layer: Epoxy (Green) |

400~800um |

||

|

Outside layer: Intensity Epoxy (Sage Green) |

||||

DN100~600 | 114.3~609.6 | 3PP: Three Layers Polypropylene | Inside Layer: Epoxy(Green | 2.5~3mm |

Mid Layer: Adhesive (White) | ||||

Outside Layer: Polypropylene (White) |

Applications

External Corrosion Protection for Steel Pipes

Single-layer FBE Coating, Two-layer FBE Coating(2FBE), Two-layer PE/PP Coating(2PE/2PP), Three-layer PE/PP Coating(3PE/3PP), Epoxy coal asphalt coatings, Polyurethane heat preservation etc.

Internal Corrosion Protection for Steel Pipes: Epoxy coating, cement mortar lining etc.