The Manufacture Process Of ERW (Electric Resitance Weld Pipe)

- Share

- Issue Time

- Sep 2,2019

Summary

ERW pipes means ERW pipe manufacturing processs. A plate rolled to become a pipe and welded using Electric Resistance Welding process. Usully for for high diameter.

The Manufacture Process Of ERW (Electric Resitance Weld Pipe)

ERW pipes means ERW pipe manufacturing processs. A plate rolled to become a pipe and welded using Electric Resistance Welding process. Usully for for high diameter.

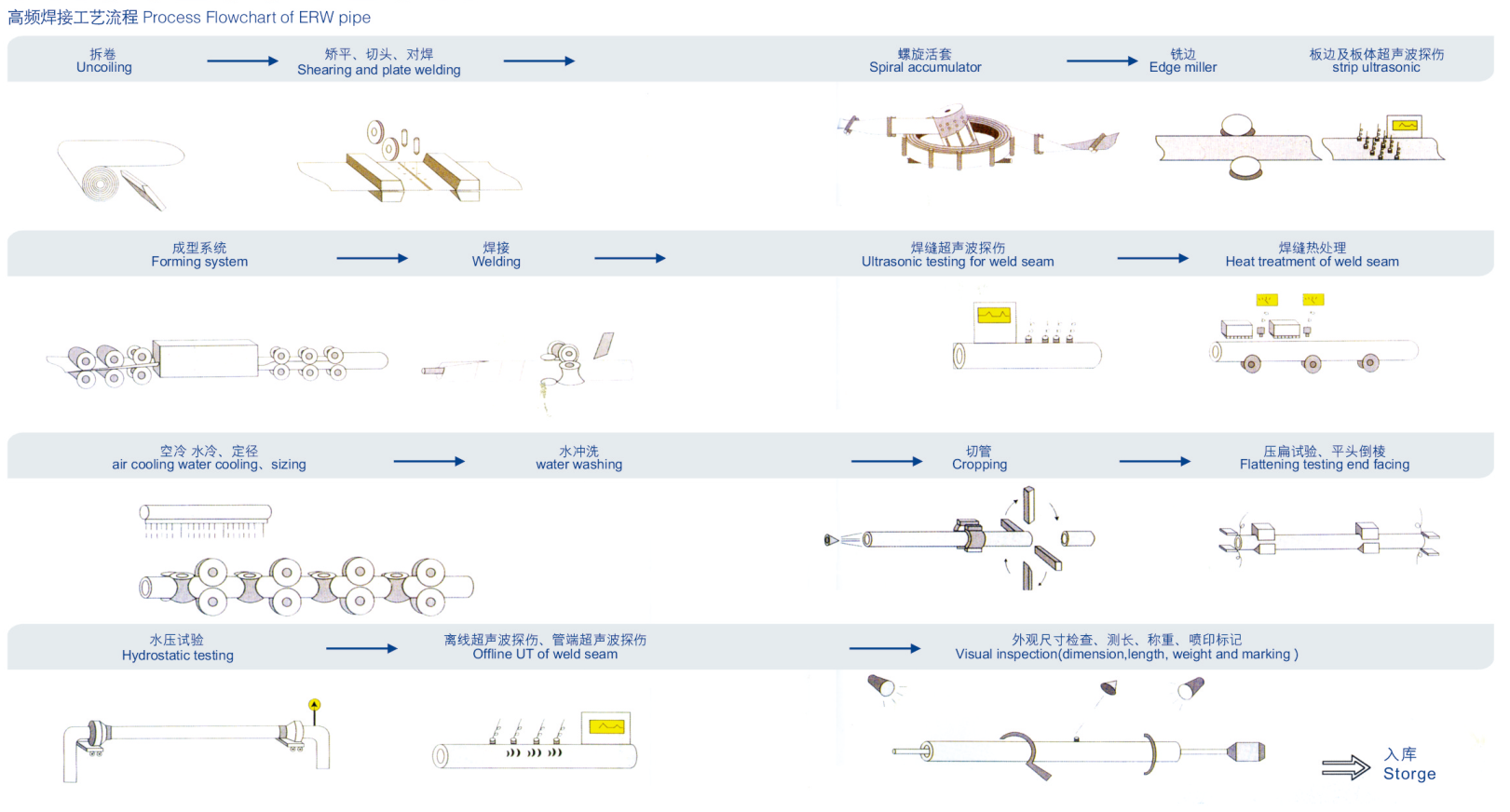

completion of these processes requires a variety of machinery and equipment and welding, electrical controls, detection devices, these devices and devices according to different. The process requires a variety of reasonable arrangement, the typical flow of high frequency welded pipe: open-book - strip leveler - head and tail cut - strip butt - looper accumulator - molding - welding - clear the glitch - sizing - flaw -fly cut - Initial verification - tube Straightening - pipe processing - hydrostatic testing - flaw detection - Printing and coating - finished.

High-frequency welding is continuously flowing through the workpiece contact surface of the high-frequency current generated by the resistance heating and forging force to impose, so that the workpiece metal to achieve a mutually successive welding method. It is similar to the ordinary resistance welding, but there are many important differences.

High-frequency welding for carbon steel welded pipe production has been 40 years of history. High-frequency welding power power of different material, diameter and wall thickness of steel pipe to achieve a higher welding speed (more than l0 times higher than the the TIG highest welding speed).

Therefore, production of general-purpose high-frequency welding steel pipe has a higher productivity of high-speed high-frequency welding, pipe within the burr removal difficult, and this is also the high-frequency welded steel pipe is not yet for the chemical, nuclear industry accepted one of the reasons. From the welding material, high frequency welding can weld all types of steel pipes. At the same time, the development of new steel grades and shaping the progress of welding methods.

ERW line pipe-- for the transportation of oil, natural gas and chemical materials

Standards: AP-5L PSL1/ PSL2 GB/T9711.1-1997 GB/T9711.2-1999Steel

Grade :A、B、X42、X46、X52、X56、X60、X65、X70

ERW Casing pipe--petroleum and nature air exploration

Standards: API SPEC 5CT, SY/T5989

Materials :H40 J55 K55

Structure and Mechanical Roundpipe and Tubing

Standards: JIS3466、JIS3445; ASTM A513; GB/T 6728-2002

Steel Materials: Carbon steel, Stainless, and low ally steel

Structure and Mechanical Square or Rectangular Pipe

Standards: GB/T3091 JIS G3452

Steel grade: Q215A、Q215B、Q235AB 、Q295AB、Q345AB

Mill Test Certificate: EN 10204/3.1B

Third party inspection: SGS, BV, Lloyds etc.

Manufacture Process of ERW steel pipe